Automated Surface Inspection | AI Manufacturing Solutions

AI-Powered Quality Inspection for Industrial Automation

Industry Event Demonstration

EZ Automation showcases PIQuE inspection system at ISA Expo. The event runs October 5-7 in Lake Buena Vista. Visitors can experience live demonstrations at Booth 310. The system represents advanced automation technology.

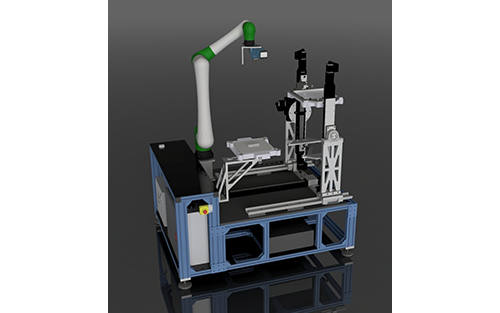

Inline Inspection Configuration

PIQuE now features new inline inspection capabilities. This design eliminates robotic manipulation components. The system integrates directly into production lines. Manufacturers achieve faster quality control processes.

Advanced Inspection Technology

The system utilizes 3D laser triangulation methods. AI-powered deep learning identifies surface defects. The technology detects scratches and dents effectively. Missing components and barcode errors become visible.

- 3D laser triangulation for precise measurement

- Deep learning algorithms for defect detection

- Adaptive learning for continuous improvement

- Cloud-based analytics for performance monitoring

Vision Processing Framework

EZ Eye platform powers the inspection system. Pre-trained AI models enable rapid deployment. The system requires minimal setup configuration. Adaptive learning handles product variations automatically.

Manufacturing Applications

PIQuE serves multiple industrial sectors effectively. Electronics manufacturing benefits from PCB inspection. Medical device production requires precise quality control. Aerospace components demand stringent surface standards.

- Electronics and semiconductor manufacturing

- Medical device production quality control

- Aerospace component inspection

- Automotive parts surface verification

Operational Advantages

The system reduces false rejection rates significantly. Historical data improves inspection accuracy continuously. Plug-and-play installation simplifies implementation. Remote monitoring enables off-site supervision.

Industry Perspective

EZ Automation CEO emphasizes solution flexibility. Ahmed Tawfik notes real-world manufacturing challenges. The system adapts to dynamic production environments. Quality control becomes more efficient and reliable.

Market Context and Trends

Industrial automation increasingly adopts AI technology. According to MarketsandMarkets, machine vision grows at 7.2% annually. Quality inspection demands higher precision levels. Automated systems reduce human error factors.

Implementation Considerations

PLCDCSHUB recommends evaluating several key factors. Production line compatibility requires verification. Integration with existing control systems needs planning. Training requirements for operational staff should be considered.

Quality Control Application

Situation: Electronics manufacturer needs PCB inspection solution.

- Solution: Implement PIQuE inline inspection system

- Components: 3D laser scanners, AI processing, cloud analytics

- Result: 95% defect detection with reduced false rejects

The system improved quality while reducing manual inspection costs.

Technical Support Services

EZ Automation provides comprehensive remote support. One-year service inclusion supports implementation. Cloud-based monitoring enables proactive maintenance. Technical assistance ensures system reliability.

Frequently Asked Questions

Q: How does AI inspection compare to traditional vision systems?

A: AI systems learn from data and improve over time, while traditional systems require manual programming and struggle with product variations. AI typically achieves 30-50% higher accuracy in complex inspection tasks.

Q: What production environments suit inline inspection systems?

A: High-volume manufacturing with consistent product flow benefits most from inline systems. Applications requiring 100% inspection at production line speeds represent ideal use cases for this technology.

Q: How difficult is system integration with existing automation?

A: Modern inspection systems feature standard communication protocols like OPC UA and Ethernet/IP, enabling relatively straightforward integration with most PLC and DCS control systems through proper planning.

For industrial automation components and vision systems, visit PLCDCSHUB for control systems and inspection technology.

Company Background

EZ Automation operates across multiple international markets. The company specializes in intelligent automation solutions. Global presence supports diverse customer requirements. Turnkey solutions address specific industry challenges.