Automated Welding and Cutting Solutions for Modern Fabrication

Universal Robots to Power Next-Gen Laser Welding, Finishing and Plasma Cutting at FABTECH 2025

Collaborative Robots Transform Industrial Automation at FABTECH 2025

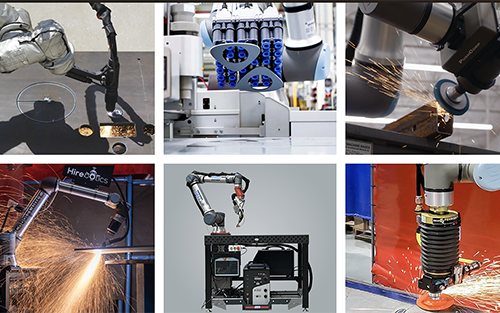

Universal Robots (UR) will showcase innovative cobot solutions at FABTECH 2025 in Chicago. These advancements target laser welding, plasma cutting, and finishing applications. The collaborative robot market continues to expand rapidly. According to MarketsandMarkets research, this sector will reach $14.3 billion by 2028. This growth reflects increasing demand for flexible automation. Therefore, UR’s latest offerings align perfectly with current industry needs.

Next-Generation UR Robot Revolutionizes Welding Applications

Universal Robots introduces a specialized welding robot at FABTECH 2025. This cobot delivers exceptional reach, stability, and precision. It handles complex welding tasks with remarkable consistency. The robot manages long seams and intricate part geometries effectively. Moreover, partners including Hirebotics and Vectis Automation will feature this new model. PLCDCSHUB analysis confirms such robots significantly reduce programming time. They integrate seamlessly with existing PLC and DCS control systems.

Automated Plasma Cutting Enhances Manufacturing Efficiency

Robotic plasma cutting represents a rapidly growing cobot application. Traditional manual cutting often produces inconsistent results. However, automated cutting generates weld-ready parts with perfect consistency. Hirebotics’ Cobot Cutter achieves precise cuts on multiple materials. Additionally, Vectis Automation enables complex shape cutting on curved surfaces. These advanced solutions substantially reduce manual rework requirements. Consequently, manufacturers achieve higher throughput and better quality.

Laser Welding Reaches Mainstream Manufacturing Adoption

Laser welding technology has overcome initial cost and safety concerns. THG Automation’s URW-2LF system combines UR robots with IPG fiber lasers. This configuration produces cleaner, faster welds with minimal distortion. Furthermore, AI-powered path optimization enhances process accuracy. PLCDCSHUB experts note laser welding benefits high-mix production environments. The technology complements distributed control systems in modern factories. Therefore, manufacturers gain significant competitive advantages.

Advanced Finishing Solutions with Smart Force Control

Finishing applications gain new capabilities through adaptive force control. PushCorp and Ferrobotics demonstrate their latest solutions at UR’s booth. These systems automatically adjust to surface variations. The AFD120 active force device ensures consistent finishing quality. Operators can program multiple tools easily. This versatility makes cobot finishing accessible for beginners. It also supports production scaling for established manufacturers.

Efficient Material Handling for Modern Fabrication

Material handling cobots optimize essential fabrication tasks. The high-speed UR15 robot pairs with Schmalz’s innovative gripper technology. This combination reduces compressed air consumption significantly. Consequently, manufacturers achieve substantial energy savings. Such advancements demonstrate how collaborative robots improve operational efficiency. They represent smart investments for forward-thinking manufacturers.

Key Applications and Implementation Benefits

- ✅ Plasma Cutting: Hirebotics delivers precise cuts on multiple materials

- ⚙️ Laser Welding: THG Automation includes advanced pre-cleaning features

- 🔧 Force Control: Ferrobotics enables adaptive finishing solutions

- 📊 Data Analytics: Vectis provides production metrics for optimization

Expert Analysis from PLCDCSHUB

The integration of collaborative robots with traditional automation continues evolving. Modern cobots communicate effectively with industrial PLCs. This compatibility ensures smooth implementation in existing facilities. Manufacturers should evaluate both technical specs and workflow impacts. For comprehensive guidance on industrial control systems, visit our technical resource center. Our experts provide detailed analysis of PLC and DCS integration strategies.

Frequently Asked Questions

How do cobots maintain consistent welding quality?

Cobots ensure repeatable weld paths and maintain optimal parameters automatically.

Can cobot systems integrate with existing factory automation?

Yes, most collaborative robots support standard industrial communication protocols.

What safety measures protect operators during laser operations?

Systems incorporate multiple safeguards including enclosures and software-based safety zones.

Discover more about industrial automation solutions at PLCDCSHUB. We provide expert analysis of control system technologies to optimize your manufacturing operations.