How to Avoid Mechanical Damage During Probe Mounting in Industrial Automation

Understanding the Stakes of Proper Probe Mounting

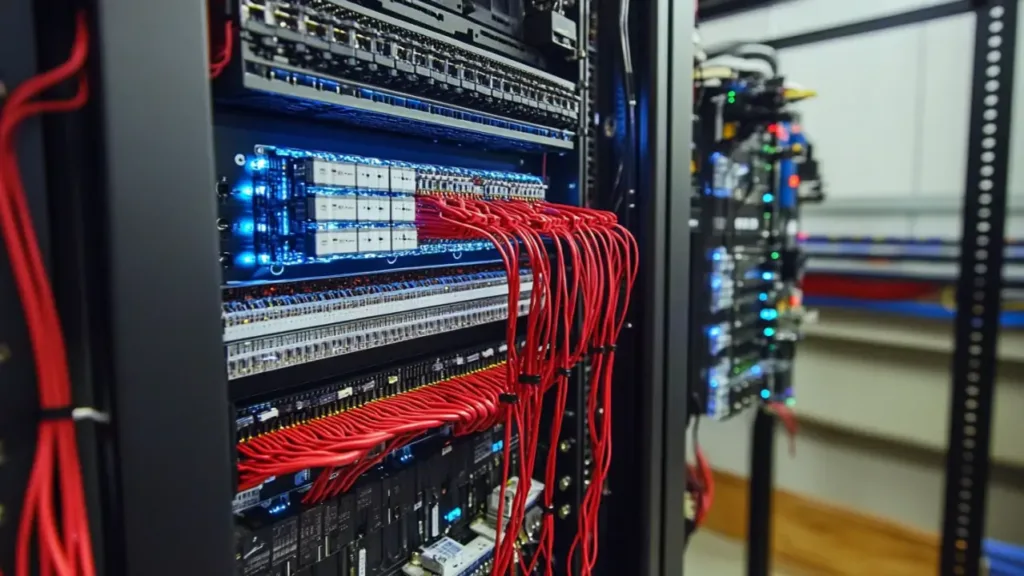

In the world of industrial automation, precise and reliable measurement is critical. Sensors and probes are the eyes and ears of your control systems, from PLC (Programmable Logic Controller) to DCS (Distributed Control System). A damaged probe can lead to inaccurate readings, system failures, and costly downtime. Therefore, understanding proper mounting techniques is essential. Mechanical damage often occurs during installation, transportation, or even routine maintenance. My experience shows that a few simple precautions can save thousands in equipment replacement and lost production. These devices are fragile and require careful handling.

Choosing the Right Mounting Location

The mounting location directly impacts the probe’s longevity. For example, in factory automation, a probe should be installed in a clean, stable area away from direct impact or excessive vibration. Avoid mounting probes near hot spots or in locations with high mechanical stress. Consider the operational environment. For instance, a proximity sensor used for machine control requires a sturdy bracket that prevents it from shifting. Conversely, a temperature probe should be positioned to avoid physical contact with moving parts. A well-planned location minimizes both installation risk and long-term operational stress.

Preparing Surfaces for Optimal Contact

Surface preparation is a crucial but often overlooked step. Dirt, burrs, and foreign particles can prevent a secure and flat mount. Always clean the mounting surface thoroughly before installation. For stud-mounted sensors, a smooth, flat machined surface ensures the best measurement results. Using a thin layer of coupling fluid, like grease, can improve high-frequency signal transmissibility. This small step ensures the sensor’s accuracy while protecting its delicate base. It prevents the need for excessive torque, which can damage the sensor or its mounting threads.

Handling Probes with Care

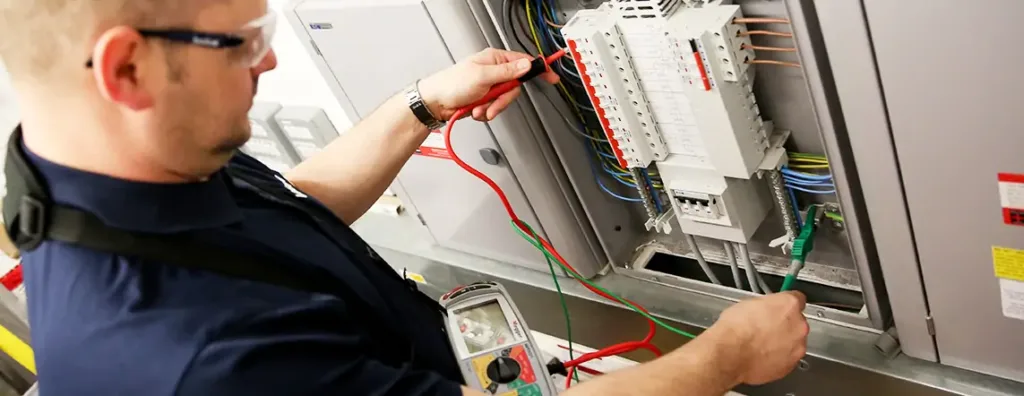

Handling is a primary cause of mechanical damage. Never touch the sensing elements with bare hands. Oils and moisture can degrade sensor performance over time. Use appropriate tools, like plastic-tipped tweezers or vacuum pickup tools, to avoid applying excessive force. During the mounting process, ensure the mounting stud does not bottom out. This can break the internal components. As a result, the probe becomes useless before it even begins operation. It’s also vital to protect exposed cables and connectors from kinks or sharp bends. This detail is important for maintaining data integrity in control systems.

Securing Cables and Connectors Properly

The probe cable is a weak point. Improper routing and strain relief can lead to damage. Always secure cables inside the bearing housing or on the machine. This prevents them from being pinched or abraded. Use cable ties or clamps to create strain relief loops. Never let cables dangle freely. My professional advice is to use armored jackets or stainless steel overbraid in harsh environments. This protects the wire from abrasion and mechanical abuse. A compromised cable can lead to signal loss, which directly impacts the reliability of your factory automation system.

The Importance of Proper Torque and Fasteners

Tightening fasteners correctly is critical. Over-tightening can deform the probe housing or damage the threads. Under-tightening can cause the probe to loosen over time due to vibration. Use a torque wrench to ensure the correct force is applied. Consult the manufacturer’s specifications for the recommended torque values. In addition, all fasteners should be properly secured. Safety wiring or using thread-locking compounds prevents screws from loosening during machine operation. This practice is standard in mission-critical applications to avoid catastrophic failure.

Practical Application Scenarios

These principles are applicable across various industries. For a chemical plant using DCS, a properly mounted pressure probe prevents leaks and ensures process safety. In an automotive assembly line, a carefully installed proximity sensor guarantees the correct positioning of robotic arms.

For a comprehensive range of high-quality probes and other industrial automation components, visit PLCDCS HUB Limited. We offer solutions that are engineered for durability and reliability, ensuring your systems perform at their best.

[Click below to explore our product offerings and find the right solution for your application.]

| Model | Title | Link |

|---|---|---|

| 330102-40-62-05-02-05 | Bently Nevada 3300 XL 8 mm Probe | Learn More |

| 330101-00-75-15-02-05 | Bently Nevada Proximity Probes | Learn More |

| 330102-40-62-05-02-05 | Bently Nevada 3300 XL 8mm Proximity Probe Without Armor | Learn More |

| 330102-00-68-05-02-05 | Bently Nevada 3300 XL 8mm Proximity Probe Without Armor | Learn More |