Industrial Automation: From Hardware to Virtual PLCs

The Evolution of PLC Technology: From Hardware to Virtualization

Programmable Logic Controllers continue evolving toward virtualization. Traditional hardware PLCs now share space with soft and virtual controllers. This transformation impacts industrial automation architecture significantly.

Traditional Hardware PLC Foundations

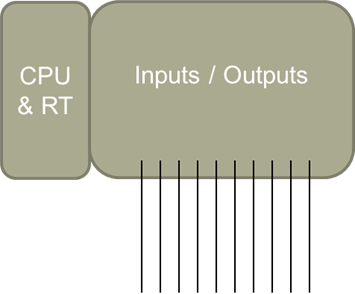

Classical PLCs represent the industry’s foundation technology. They combine proprietary hardware with integrated runtime systems. These controllers provide reliable real-time performance. Moreover, they achieve cycle times under 1 millisecond for critical applications.

Remote I/O System Advancements

Remote I/O systems separate sensor interfaces from central controllers. This architecture supports larger facility layouts efficiently. Standardized fieldbus protocols enable multi-vendor compatibility. Consequently, manufacturers achieve greater installation flexibility.

Soft PLC Technology Evolution

Soft PLCs separate runtime software from specific hardware platforms. They operate on various processors and operating systems. This approach increases deployment flexibility substantially. Furthermore, it reduces hardware dependency for control applications.

Virtual PLC Implementation

Virtual PLCs represent the latest evolutionary stage. They run on servers using container or hypervisor technology. This enables centralized management and scalability. However, network latency becomes a critical performance factor.

Performance Comparison Across PLC Types

- Hard PLCs: Sub-millisecond cycle times for motion control

- Soft PLCs: 1-10ms cycles for most factory automation

- Virtual PLCs: 10-150ms depending on network configuration

- Cloud PLCs: Limited to non-critical applications currently

Market Adoption and Vendor Landscape

Leading automation companies now offer virtual PLC solutions. Siemens provides SIMATIC S7-1500V for cloud deployment. Beckhoff offers TwinCAT for Linux environments. CODESYS delivers container-based control solutions. These products enable new automation architectures.

Industrial Implementation Case Study

Audi implemented virtual PLCs in their Neckarsulm facility. The axle assembly line uses Siemens S7-1500V controllers. This cloud-based approach centralized management functions. The system has operated successfully since January 2024.

Communication Protocol Requirements

Virtual PLCs demand robust industrial networking. PROFINET and EtherCAT ensure deterministic performance. Time-Sensitive Networking standards address latency challenges. Furthermore, security becomes increasingly crucial in distributed architectures.

Standardization Initiatives

IEC 61131-3 establishes programming language standards. IEC/IEEE 60802 defines TSN profiles for automation. China develops GB/T standards for virtualization architecture. These efforts support technology interoperability.

Industry Growth Projections

The industrial automation market expands rapidly. According to MarketsandMarkets, it will reach $306 billion by 2027. Virtualization represents the fastest-growing segment. Companies seek flexibility and reduced hardware costs.

PLCDCSHUB Technical Analysis

At PLCDCSHUB, we observe virtualization’s practical implications. Traditional industrial automation systems face architectural evolution. Virtual PLCs suit applications with moderate timing requirements. However, hard PLCs remain essential for safety-critical functions. We recommend evaluating application requirements before technology selection.

Implementation Considerations

- Assess network infrastructure for latency and reliability

- Evaluate security requirements for distributed systems

- Consider maintenance and update procedures

- Analyze total cost of ownership across lifecycle

- Plan for hybrid architectures combining PLC types

- Train staff on new management tools and procedures

Frequently Asked Questions

- What applications suit virtual PLCs best? Batch processes, material handling, and energy management systems typically work well with virtual PLCs where cycle times above 10ms are acceptable.

- How do virtualization technologies affect system reliability? Properly implemented virtual PLCs can improve reliability through centralized management and redundancy, though network dependencies introduce new failure points.

- What skills do maintenance teams need for virtual PLCs? Teams require networking knowledge, container management skills, and understanding of cloud infrastructure in addition to traditional PLC programming expertise.

This technical analysis was provided by PLCDCSHUB, delivering expert insights on industrial automation and control system technologies.

Explore control system solutions for your automation needs. Visit PLCDCSHUB for components and implementation expertise.