Mastering Probe Accuracy in Moisture-Prone Industrial Environments

How to Maintain Probe Accuracy in Moisture-Prone Areas

Industrial processes often take place in environments with high humidity. Factories producing food and beverages, pharmaceuticals, or chemicals face significant challenges. Maintaining probe accuracy in these moisture-prone areas is critical. Inaccurate data from a faulty sensor can lead to production issues. For example, it might cause product quality problems or even system failures. Therefore, proper maintenance of sensors is not just good practice; it is a necessity for efficient industrial automation. This article explores key strategies for ensuring your probes remain reliable.

Selecting the Right Sensors for Humid Conditions

The first step to success is choosing the correct hardware. Not all sensors are created equal. High-quality control systems depend on robust sensors designed for harsh environments. When selecting a probe, you should consider its IP rating (Ingress Protection). A higher IP rating, like IP67 or IP68, indicates better resistance to dust and water. Moreover, look for probes with protective filters. These filters shield the sensing element from contaminants without blocking moisture. This feature is especially crucial in applications like fermentation or food processing. My experience suggests that investing in durable, purpose-built sensors from reputable brands pays for itself.

Implementing a Regular Calibration Schedule

Calibration is the cornerstone of accurate measurement. Over time, all sensors drift from their original factory settings. Environmental factors such as temperature swings and humidity levels accelerate this drift. Implementing a regular calibration schedule ensures your probes provide correct data. For a PLC or DCS to make accurate decisions, it must receive reliable inputs. For critical applications, monthly or even weekly calibration may be necessary. Always follow the manufacturer’s recommendations. You must also keep detailed records of all calibration activities.

Shielding Probes from Direct Moisture

Even the most robust probes benefit from physical protection. You can use protective housings or enclosures to shield sensors from direct water spray or condensation. When a probe is directly exposed, its readings can become unstable. Condensation on a sensor element creates a temporary short circuit. As a result, the probe provides erroneous readings. Consider an application in a steam sterilizer. Here, a well-designed housing prevents direct contact with steam. This simple step significantly improves measurement stability. Ultimately, this leads to better process control and improved efficiency.

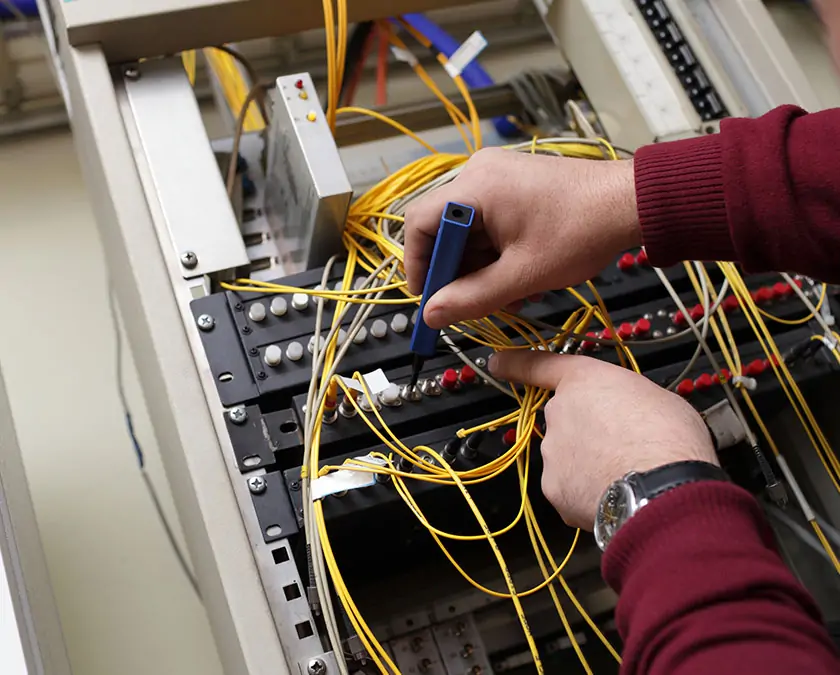

Developing a Proactive Maintenance Routine

A reactive approach to maintenance can be costly. Instead, a proactive routine saves time and money. Regularly cleaning probe surfaces removes accumulated dirt and grime. This debris can interfere with accurate readings. Furthermore, a thorough inspection can identify signs of corrosion or physical damage. A damaged probe must be replaced immediately. In a large factory automation system, integrating predictive maintenance is a great idea. Modern systems use data analytics to predict when a probe might fail. This allows for planned replacements, avoiding unscheduled downtime. This approach ensures maximum uptime and productivity.

The Role of PLC and DCS in Moisture Control

Probe accuracy is meaningless without a smart control system. A modern PLC or DCS processes data from moisture sensors. It then adjusts actuators to maintain optimal conditions. For example, in a drying process, the control system receives moisture data. It then modulates a heating element to reach a target humidity. A well-designed control systems architecture also incorporates redundancy. Using multiple probes can cross-verify readings. When one probe shows a suspicious value, the system can cross-reference it with others. This prevents a single faulty sensor from shutting down an entire process. This is a common practice in mission-critical applications.

Applications and Solutions

Accurate moisture measurement is vital in many industries. In the textile industry, moisture control ensures consistent fabric quality. In the food and beverage sector, it prevents spoilage. We at PLCDCS HUB Limited offer robust solutions for all these applications. Our industrial-grade sensors and custom control systems are designed for challenging environments. We help you achieve unparalleled accuracy and reliability.

Ready to improve your industrial processes? Click here to explore our products and solutions.