Non-Invasive Temperature Sensors Revolutionize Data Center Cooling

Revolutionizing Data Center Cooling with Non-Invasive Temperature Measurement

The Shift to Liquid Cooling in Modern Data Centers

Hyperscale data centers are rapidly adopting liquid cooling solutions. This transition addresses growing thermal management challenges. High-performance computing and AI workloads generate intense heat. Traditional air cooling cannot handle these thermal loads effectively. According to MarketsandMarkets, the liquid cooling market will reach $8.6 billion by 2027. Liquid cooling provides superior heat transfer capabilities. Therefore, it prevents hotspots and maintains optimal operating temperatures.

Traditional Temperature Measurement Challenges

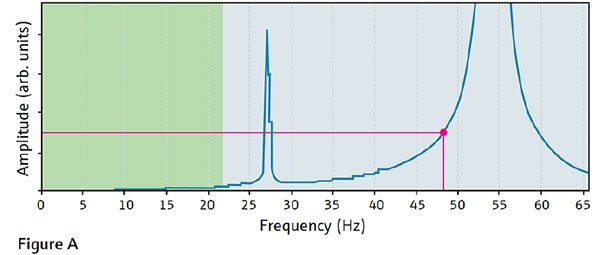

Conventional cooling systems use invasive temperature sensors. These include thermocouples and RTDs inside thermowells. However, these traditional methods present several operational risks. They can cause leakage points and potential contamination. Additionally, they create flow disturbances that reduce system efficiency. Thermowells require complex engineering calculations. Wake frequency analysis prevents vibration-induced failures. Moreover, these invasive sensors increase pump energy consumption. They create pressure drops that strain the cooling system.

Critical System Reliability Factors

Pump performance remains crucial in liquid-cooled data centers. Any flow disruption can cause immediate temperature spikes. Consequently, these spikes risk damaging expensive hardware components. Cooling loop cleanliness is equally important. Contaminants include particulate matter and biological growth. They can cause blockages and corrosion damage. Regular maintenance ensures water purity and system reliability. Filtration and chemical treatments prevent performance degradation. These measures maintain optimal cooling efficiency.

Non-Invasive Measurement Innovation

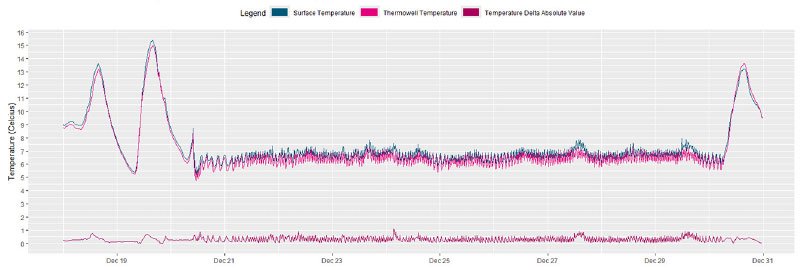

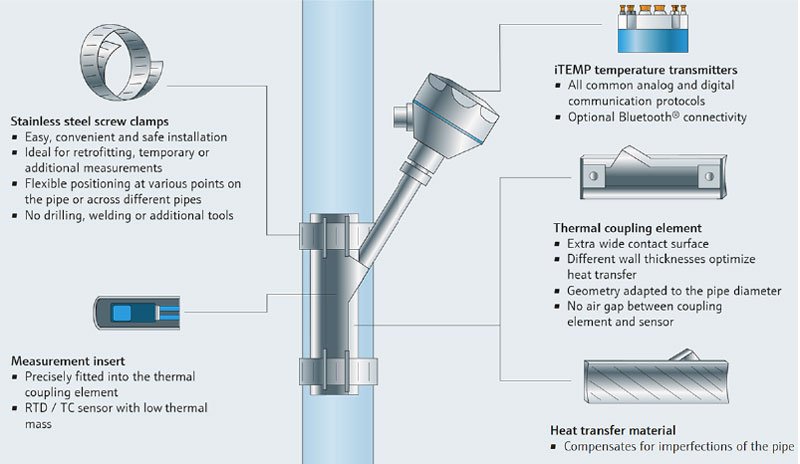

Endress+Hauser’s iTHERM SurfaceLine TM611 offers a breakthrough solution. This non-invasive sensor eliminates process penetration entirely. It uses a mechanical clamp-on interface design. This approach provides several significant advantages. It maintains system cleanliness and prevents contamination. The design minimizes flow disturbances and pressure drops. Therefore, pumps operate more efficiently with lower energy consumption. The sensor delivers accuracy comparable to invasive thermometers.

Technical Advantages for Data Center Applications

The TM611 sensor excels in critical cooling applications. It handles high flow velocities and corrosive media effectively. The mechanical interface minimizes ambient temperature effects. This provides faster response times and superior accuracy. Unlike electronic compensation methods, it uses physical design principles. The sensor requires minimal maintenance over its lifespan. It reduces total cost of ownership for data center operators. Additionally, it supports sustainable operations through energy efficiency.

Implementation Benefits and Performance Metrics

Data centers achieve multiple benefits with this technology. They experience reduced contamination risks in cooling loops. Pump energy consumption decreases significantly. Maintenance intervals extend due to non-invasive design. System reliability improves with consistent temperature monitoring. According to IEEE research, proper temperature control can reduce cooling costs by 25%. The technology supports continuous operations in critical environments.

Practical Application Scenarios

✅ Hyperscale Data Centers: Ideal for AI and HPC cooling systems

⚙️ High-Flow Environments: Maintains accuracy in turbulent conditions

🔧 Corrosive Media Applications: Resists chemical degradation

💧 Cleanroom Environments: Prevents contamination risks completely

Expert Commentary from PLCDCSHUB

Non-invasive measurement represents the future of industrial automation. The iTHERM SurfaceLine TM611 demonstrates significant engineering innovation. However, successful implementation requires proper system integration. Data center operators should consider their specific cooling requirements. For comprehensive information about industrial automation solutions, visit PLCDCSHUB. Our platform offers detailed technical resources and product comparisons.

Frequently Asked Questions

How accurate are non-invasive temperature sensors?

Modern non-invasive sensors like the TM611 achieve accuracy comparable to invasive thermometers. They typically provide ±0.5°C accuracy in most applications.

Can these sensors handle high-pressure cooling systems?

Yes, the TM611 is designed for high-pressure applications. It can withstand pressures up to 100 bar in cooling systems.

What maintenance do non-invasive sensors require?

They require minimal maintenance compared to invasive sensors. Regular calibration and surface inspection ensure long-term accuracy.