Parallel Pump System Optimization for Industrial Energy Savings

Optimizing Parallel Pump Systems for Industrial Energy Efficiency

Industrial facilities achieve significant energy savings through optimized parallel pump operations. Variable speed drives and intelligent control strategies reduce power consumption dramatically. This approach benefits water distribution, HVAC systems, and industrial processes.

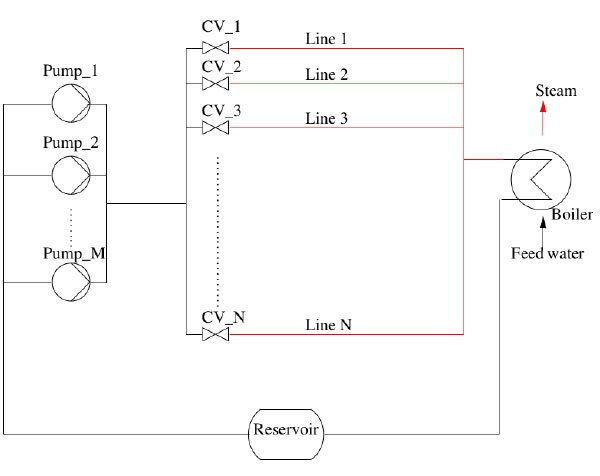

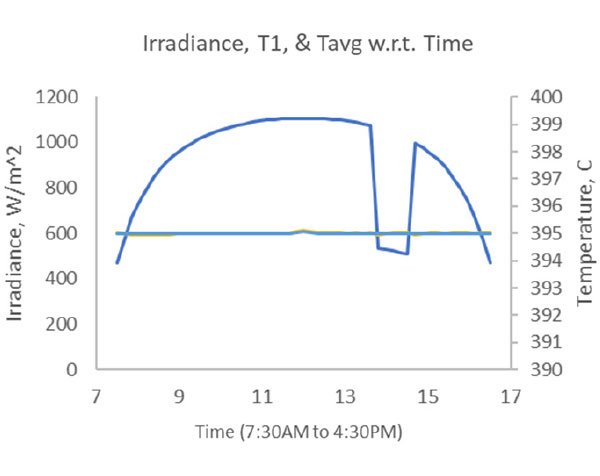

Solar Thermal Plant Case Study Overview

The Plataforma Solar de Almeria research center demonstrates pump optimization. Their parabolic trough collectors heat thermal oil to 400°C. This generates steam for turbo generators efficiently. Flow requirements change significantly throughout daylight hours. The system handles 3:1 flow ratio variations effectively.

Parallel Pump System Advantages

Multiple smaller pumps outperform single large units consistently. They provide better reliability through redundancy. Maintenance becomes easier with standardized components. Capital costs decrease with off-the-shelf items. Furthermore, system flexibility improves significantly.

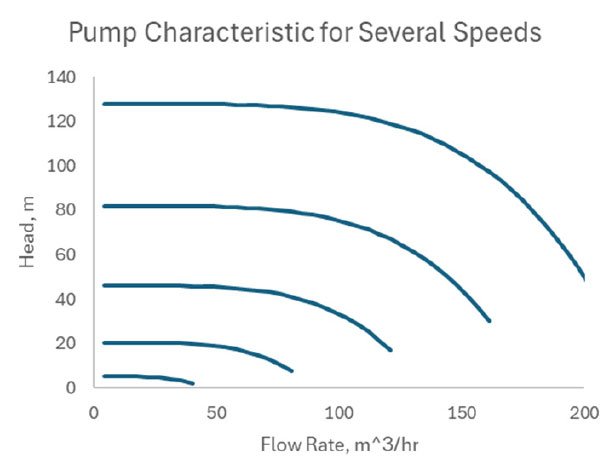

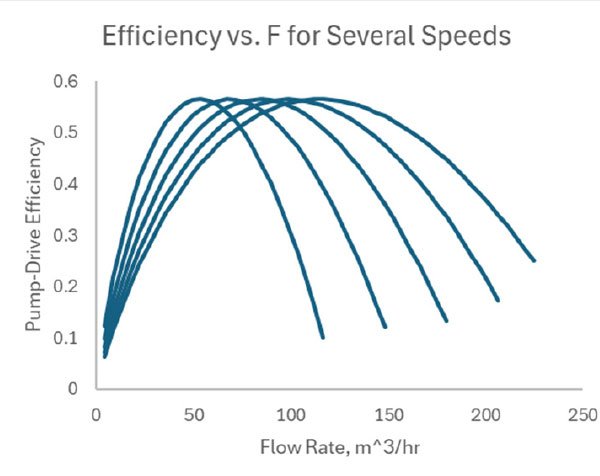

Variable Speed Drive Benefits

Variable speed drives outperform throttling valves considerably. They adjust pump speed to match exact flow requirements. This reduces energy consumption by up to 90% in some cases. Motor wear decreases with optimized operation. Maintenance intervals extend substantially as a result.

Control System Implementation

Advanced control systems manage parallel pump operations intelligently. They determine optimal pump numbers and speeds continuously. Model-based control uses first-principles calculations. PLC and DCS systems execute optimization algorithms. These systems maintain precise temperature control throughout.

Energy Savings and Performance Results

Optimized systems achieve 3.4% daily power savings consistently. Fewer pumps operate near their best efficiency point. This reduces operational wear and maintenance costs. Power consumption drops dramatically during low-demand periods. The strategy also extends equipment lifespan significantly.

Industry Applications and Market Context

The global industrial pumps market will reach $75.3 billion by 2028 according to MarketsandMarkets. Variable frequency drive adoption grows at 9.1% annually according to IEEE reports. From PLCDCSHUB’s perspective, this optimization approach applies to multiple industries. Water treatment plants and HVAC systems benefit particularly. Manufacturing facilities achieve quick return on investment.

Key Implementation Strategies

✅ System Analysis: Assess current pump operations and energy consumption

⚙️ Control Integration: Implement PLC-based optimization algorithms

🔧 Drive Selection: Choose appropriate variable frequency drives

📊 Monitoring Systems: Track performance and savings continuously

Practical Application Scenarios

Municipal water systems reduce energy costs significantly. HVAC operations in large buildings optimize pump usage. Industrial process plants maintain precise flow control. Renewable energy facilities maximize operational efficiency. All applications benefit from reduced maintenance requirements.

Industrial automation professionals recognize pump optimization importance. Discover comprehensive resources for control systems and energy management at PLCDCSHUB. Our platform provides expert guidance for implementing efficient pump control strategies.

Frequently Asked Questions

What are the main benefits of parallel pump systems?

They provide redundancy, reduce maintenance costs, and enable optimized operation. Energy savings typically reach 20-50% in variable flow applications.

How do variable speed drives save energy?

They match pump speed exactly to flow requirements. This eliminates energy waste from throttling valves and reduces motor power consumption.

Can existing pump systems be retrofitted for optimization?

Yes, most systems can integrate variable speed drives and control upgrades. Return on investment typically occurs within 12-24 months.