Description

High-Precision Machinery Health Monitoring Solution

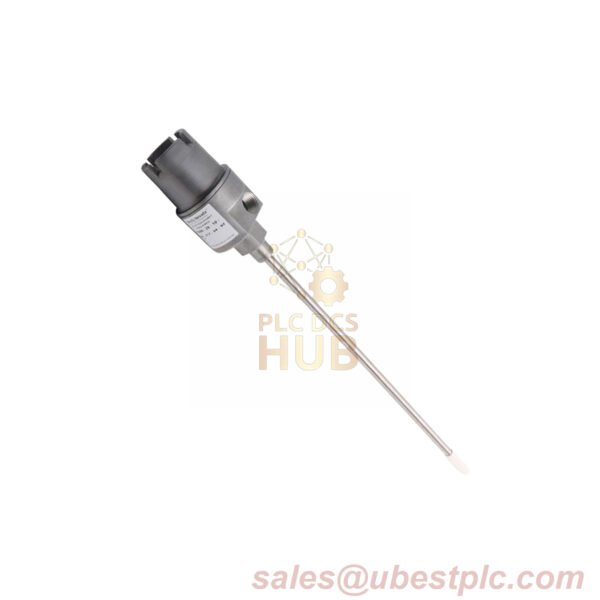

The Bently Nevada 21000-28-05-00-092-03-02 features an industry-leading 9.2″ (234 mm) probe penetration depth, engineered for heavy-duty industrial automation systems requiring deep-reach vibration analysis. With multi-size cable management and CSA Type 4 certification, this assembly delivers API 670-compliant predictive maintenance in Class II Division 1 hazardous environments.

Critical Technical Specifications

- Manufacturer: Bently Nevada

- Linear Range: ±2% FS across 0-8 mm

- Frequency Response: 0.5-12 kHz (±1.5 dB)

- Temp Tolerance: -40°C to +120°C continuous

- Cable Rating: 600V RMS, 90°C rated

- Housing Integrity: NEMA 4X/IP67 protection

Suffix Code Breakdown for 21000-28-05-00-092-03-02

- 28: 3300 XL 8mm probe (CSA/ATEX/IECEx)

- 05: 0.5m high-flex cable (20″)

- 00: Direct-mount configuration

- 092: 9.2″ (234mm) penetration depth

- 03: NPT plug + reducer + tri-seal cable grip

- 02: 3/4-14 NPT threading

Installation Benefits

Optimized for deep-bearing monitoring in turbomachinery, featuring ±0.25% thermal stability across operating range. The triple-seal cable grip accommodates 1/8″-3/8″ cables for flexible PLC/SCADA integration.

Compliance Certifications

- CSA: Class I Div 1 Gr B, Class II Div 1 Gr E

- ISO 13373-1: Vibration analysis standard

- NACE MR0175: Sulfide stress cracking resistant

Package Contents

- Extended 9.2″ 304SS probe sleeve

- 3/4″-to-1/2″ NPT reducer

- Three-range cable seal assembly

- High-temp fluorocarbon O-rings

- 12-month performance warranty

Industrial Automation Use Case

Implemented in hydroelectric turbine shafts for runout measurement, achieving 0.8µm resolution in high-humidity environments. Enables automated lubrication control through 4-20mA output when vibration exceeds 6.3 mm/s peak-to-peak.

Expert Support: Contact sales@ubestplc.com for hazardous area installation schematics.

0.0 Average Rating Rated (0 Reviews)