Description

Advanced Proximity Monitoring Solution for Industrial Automation

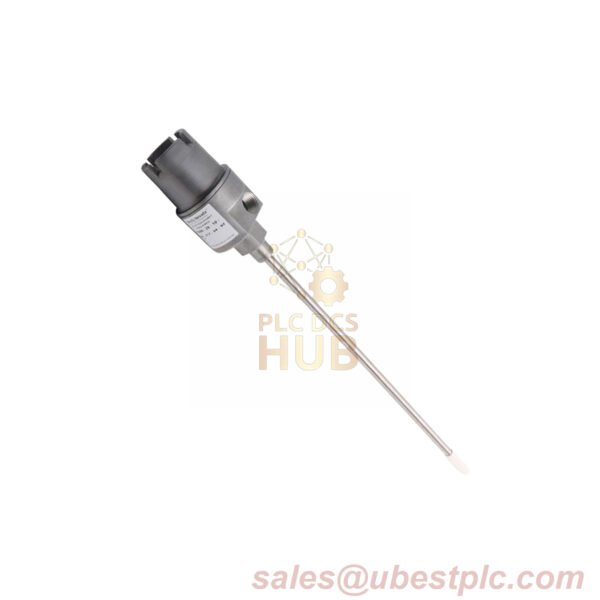

The Bently Nevada 21000-28-05-20-037-04-02 delivers explosion-proof machinery protection with 3.7″ (94 mm) probe penetration, specifically engineered for tight-clearance industrial automation systems. Featuring CSA Type 4 certification and API 670 compliance, this assembly enables predictive maintenance in Class II Division 1 hazardous zones.

Precision Technical Specifications

- Manufacturer: Bently Nevada

- Housing Material: Aluminum body with 304SS sleeve

- Measurement Range: 8 mm ±0.75% FS

- Frequency Response: 0.5-12 kHz (±3 dB)

- Temp Resilience: -58°F to +176°F (-50°C to +80°C)

- Cable Jacket: FEP-coated for chemical resistance

Suffix Decoding Matrix for 21000-28-05-20-037-04-02

- 28: 3300 XL 8 mm probe (ATEX/IECEx optional)

- 05: 0.5 m high-flex cable

- 20: 2″ (51 mm) stainless standoff adapter

- 037: 3.7″ probe penetration depth

- 04: Single 3/4-14 NPT port plug

- 02: NPT-threaded mounting

Installation Features

Optimized for vertical shaft monitoring with 2″ standoff clearance. NEMA 4X-rated enclosure withstands washdown environments. Compatible with Modbus-enabled control systems for real-time vibration analytics.

Certification Portfolio

- CSA: Class I Div 1 Gr C/D, Class II Div 1 Gr F

- ISO 10816: Vibration severity compliance

- IP67: Ingress protection rating

Complete Package

- Reverse-mount 8 mm proximity probe

- 2″ corrosion-resistant standoff

- 3/4-14 NPT blanking plug

- High-temp silicone O-rings

- 12-month anti-corrosion warranty

Industry-Specific Application

Implemented in food processing conveyors for bearing fault detection, achieving 0.002″ (0.05 mm) resolution in dusty Class II environments. Enables automated shutdown protocols through PLC integration when vibration thresholds exceed 4.5 mm/s RMS.

Technical Support: Email sales@ubestplc.com for hazardous area installation diagrams.

0.0 Average Rating Rated (0 Reviews)