Description

Product Overview

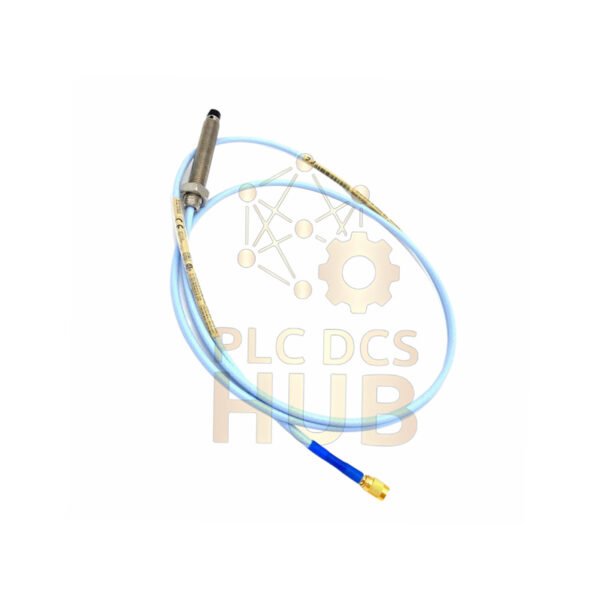

The Bently Nevada 330101-39-63-10-12-05 is a high-performance 8mm eddy current probe. It is part of the reliable 3300 XL series. This probe is designed for precise vibration and position measurement in industrial machinery. It ensures robust and reliable monitoring.

Key Features & Benefits

- Superior Durability: The 8mm body and patented TipLoc molding create a very rugged probe. It resists physical damage in tough environments.

- Secure Connection: Patented CableLoc design gives 75 lbf pull strength. This keeps the cable firmly attached to the probe tip.

- FluidLeak Prevention: Optional FluidLoc cable stops oil and liquids from leaking through the cable interior. It protects your machine.

- Wide Compatibility: Works seamlessly with Bently Nevada 3300 XL monitoring systems. It is ideal for critical asset protection.

Technical Specifications

- Brand & Model: Bently Nevada 3300 XL 8 mm Probe

- Part Number: 330101-39-63-10-12-05

- Unthreaded Length: 3.9 inches (Option 39)

- Overall Case Length: 6.3 inches (Option 63)

- Total Length: 1.0 meter / 3.3 feet (Option 10)

- Connector: Miniature coaxial ClickLoc (Option 12)

- Approvals: CSA, ATEX, IECEx (Option 05)

- Measurement & Performance

- Linear Range: 2.0 mm (80 mils). Range is from 0.25 mm to 2.3 mm from the target.

- Recommended Gap (Radial): 1.27 mm (50 mils) for -9 Vdc output.

- Sensitivity (ISF): 7.87 V/mm ±5% (200 mV/mil) for 1m/5m systems.

- Linearity (DSL): Better than ±0.025 mm (±1 mil) for 1m/5m systems.

- Frequency Response: Dependent on field wiring length. Use graphs in manual for specifics.

- Physical & Environmental Data

- Probe Tip Material: Rugged Polyphenylene Sulfide (PPS).

- Case Material: AISI 303/304 Stainless Steel.

- Temperature Range (Standard): -52°C to +177°C (-62°F to +350°F).

- Pressure Seal: Viton® O-ring design for differential pressure.

- Humidity: Less than 3% ASF change at 93% RH for 56 days.

- Electrical Data

- Probe Resistance (RPROBE): 7.59 Ω ± 0.50 Ω for 1.0m length.

- Cable Capacitance: 69.9 pF/m (21.3 pF/ft) typical.

- Field Wiring: Use 3-conductor shielded triad cable, 0.2-1.5 mm². Max 305m to monitor.

Installation & Compatibility

This 8mm probe has a 3/8-24 UNF thread. The unthreaded length is 3.9 inches. It connects using a Miniature Coaxial ClickLoc connector. We recommend a gap setting of 1.27 mm for radial vibration. This ensures optimal -9 Vdc output. The probe is compatible with all 3300 XL Proximitor Sensors and monitors.

Certifications & Approvals

This product carries major international approvals. It meets CSA, ATEX, and IECEx standards for use in hazardous and industrial locations. This ensures global acceptance and safety.

Packaging & Shipping

- Package Includes: One 3300 XL 8mm Probe (P/N 330101-39-63-10-12-05).

- Warranty: 12-month limited warranty from date of shipment.

- Shipping: We ship worldwide via FedEx, UPS, and DHL. Tracking is provided.

Typical Applications & Diagnostics

This probe is perfect for monitoring radial vibration and position on:

Rotating machinery like turbines, compressors, and pumps.

It provides key data for predictive maintenance programs.

The high signal quality helps diagnose:

Unbalance, Misalignment, Bearing Issues, and Shaft Rubs.

Frequently Asked Questions (FAQ)

What is the best gap to set for this probe?

Set the gap to 1.27 mm (50 mils). This gives a -9 Vdc output. It is the sweet spot for radial vibration measurement.

Can this probe handle high temperatures?

Yes. The standard probe works from -52°C to +177°C. For higher heat up to 218°C at the tip, ask about the Extended Temperature Range model.

How does the FluidLoc cable help?

It prevents fluid ingress. Oil or process liquid cannot travel inside the cable. This stops leaks from the machine casing. It improves safety and cleanliness.

What is the main advantage of the 8mm design?

It is much stronger. The thicker body and encapsulation protect the coil. It survives better in harsh environments with physical contact risk.

From experience, what causes probe failure?

Most failures come from mechanical damage. Avoid hitting the tip during installation. Also, do not expose the seal to below -34°C regularly. This can crack the seal over time.

Is calibration needed after installation?

No. The probe has built-in interchangeability. The system scale factor is very stable. You can replace a probe without recalibrating the entire system in most cases.

Copyright © 2025 PLCDCS HUB Limited. All rights reserved.

Partner: Powergear X Automation Limited | Oiltech Controls Limited

Contact: +86 158 8020 0923

0.0 Average Rating Rated (0 Reviews)