Siemens Leads Gartner Magic Quadrant for Industrial IoT

Siemens Named Leader in Gartner Magic Quadrant for Industrial IoT Platforms

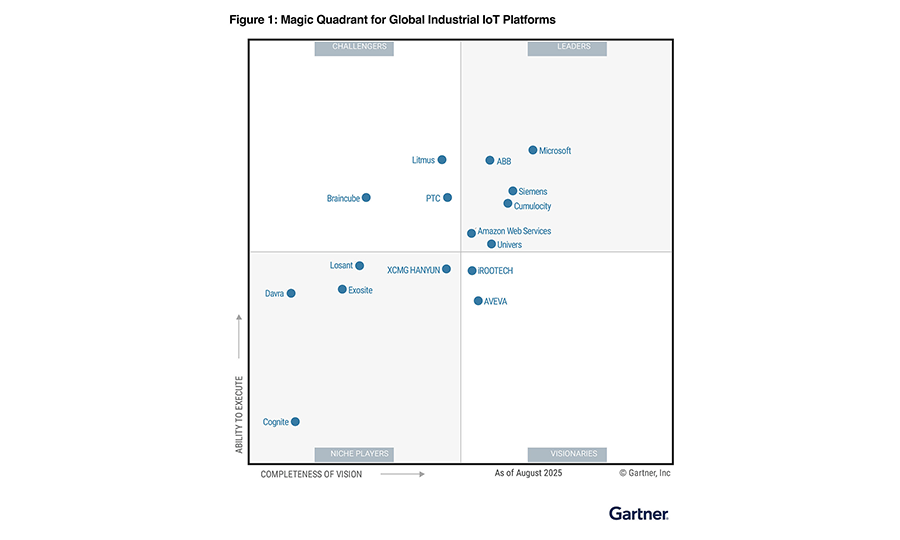

Siemens achieves leadership position in global Industrial IoT platform evaluation. Gartner recognizes the company’s strong execution capabilities and strategic vision. This acknowledgment reflects Siemens’ growing influence in industrial digitalization.

Gartner Magic Quadrant Leadership Recognition

Siemens Digital Industries Software earns Leader position in 2025 evaluation. Gartner assesses companies based on execution and vision criteria. Leaders demonstrate exceptional technology performance and market influence. Moreover, they consistently exceed customer expectations with their solutions.

Executive Leadership Perspective

Dr. Ralf M. Wagner leads Siemens Insights Hub division. He emphasizes customer trust in Siemens’ digital transformation capabilities. The company focuses on efficiency improvement and sustainability goals. Furthermore, they create long-term business value for industrial customers.

Evaluation Criteria and Market Position

Gartner evaluates both execution capability and strategic vision. Siemens improved from Visionary to Leader quadrant position. This advancement reflects increased investment in data-driven solutions. Additionally, AI innovation and global deployment flexibility contributed significantly.

Siemens Insights Hub Capabilities

The platform connects and manages industrial assets worldwide. It provides real-time insights through AI and analytics. Customers optimize operations and reduce costs effectively. The solution also supports sustainability target achievement across industries.

Industrial IoT Market Context

The global IIoT market demonstrates substantial growth momentum. According to MarketsandMarkets, it will reach $110.6 billion by 2028. Manufacturing represents the largest application segment. Companies increasingly adopt IIoT for operational efficiency improvements.

Technology Integration with Industrial Automation

Siemens IIoT platforms integrate with existing control systems seamlessly. They connect PLC and DCS infrastructure to cloud analytics. This enables predictive maintenance and optimization capabilities. Consequently, manufacturers achieve higher equipment effectiveness rates.

Key Platform Advantages

- Global asset connectivity and management

- Real-time AI-powered analytics

- Flexible deployment options

- Sustainability performance tracking

- Operational cost reduction tools

- Scalable architecture for growth

Industry Impact and Customer Benefits

Manufacturers achieve significant operational improvements through IIoT adoption. Typical implementations reduce downtime by 20-30%. Energy consumption decreases through optimized equipment operation. Furthermore, maintenance costs decline through predictive capabilities.

PLCDCSHUB Industry Analysis

At PLCDCSHUB, we monitor IIoT’s growing role in industrial automation. Siemens’ leadership position reflects market maturity. The integration between industrial automation systems and IIoT platforms becomes increasingly crucial. We observe rising demand for connected control system solutions. This trend supports more intelligent and efficient manufacturing operations.

Manufacturing Implementation Scenario

Consider an automotive parts manufacturer implementing Siemens IIoT. The system connects existing PLC controls to cloud analytics. Real-time monitoring identifies production bottlenecks immediately. Predictive maintenance prevents unexpected equipment failures. This approach improves overall equipment effectiveness by 15%.

Frequently Asked Questions

- What distinguishes Leaders in Gartner’s Magic Quadrant? Leaders demonstrate both strong execution capability and comprehensive strategic vision, consistently delivering superior customer outcomes.

- How does IIoT integration affect existing automation systems? Properly implemented IIoT enhances existing PLC and DCS systems without requiring replacement, adding analytics and remote monitoring capabilities.

- What implementation challenges do companies typically face? Organizations often struggle with data integration, security concerns, and staff training when adopting comprehensive IIoT solutions.

This industry analysis was provided by PLCDCSHUB, delivering expert insights on industrial automation and digital transformation technologies.

Explore automation and connectivity solutions for your facility. Visit PLCDCSHUB for control system components and integration expertise.