Sustainable Electronics Manufacturing with Nordson Systems

Nordson Enables Sustainable Electronics Manufacturing with PFAS-Free Coatings

Electronics manufacturers face increasing sustainability challenges. Traditional coatings often contain harmful PFAS chemicals. Nordson Electronics Solutions now offers an eco-friendly alternative. Their systems integrate seamlessly with actnano’s innovative coatings.

The Sustainable Manufacturing Challenge

PFAS chemicals pose environmental and health risks. Many countries now regulate these substances strictly. Electronics manufacturers need compliant solutions. However, performance cannot be compromised.

The global electronics manufacturing market exceeds $500 billion annually. According to Statista, environmental regulations continue tightening worldwide. Companies must adapt quickly to remain competitive.

Nordson-Actnano Technology Integration

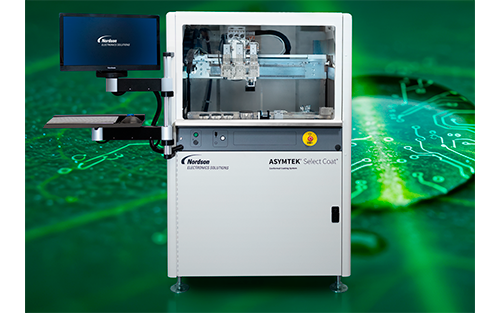

Nordson’s ASYMTEK conformal coating systems now support actnano materials. The Advanced nanoGUARD coatings eliminate PFAS completely. These coatings also remove need for curing ovens. This reduces energy consumption significantly.

Compatible systems include:

- ASYMTEK Select Coat SL-940 platform

- ASYMTEK Select Coat SL-1040 system

- Multiple reservoir and applicator options

- Integrated cleaning and filtration systems

Industrial Automation Advantages

This integration benefits factory automation environments. The systems connect with existing production lines easily. They interface with PLC and DCS control systems. This enables seamless process integration.

According to PLCDCSHUB analysis, “Sustainable manufacturing technologies represent the future of industrial automation. Nordson’s approach demonstrates how environmental goals align with operational efficiency.”

Key Technical Features

Nordson’s equipment ensures optimal coating performance. Specialized features handle actnano’s unique material properties. These maintain consistency and prevent defects.

- Agitating reservoirs prevent particle settling

- Circulating fluid systems maintain material consistency

- SC-350 Select Spray and SC-400 Precise CoatJet applicators

- Advanced filtration manages particle accumulation

- Dual ultrasonic cleaning increases uptime

Energy Efficiency Benefits

Actnano coatings eliminate energy-intensive curing ovens. This reduces factory power consumption dramatically. Manufacturers lower their carbon footprint immediately. Production costs decrease accordingly.

MarketsandMarkets research shows sustainable manufacturing growing at 12.5% annually. Energy efficiency remains a primary driver for technology adoption.

Industry Leadership Perspectives

Almar Thewissen, Nordson Market Development Manager, emphasizes the partnership’s value. “We help manufacturers shift to greener materials effectively. Our equipment maintains high quality while improving workplace safety.”

Dr. Cassandra Zentner of actnano highlights dual benefits. “This partnership advances both sustainability and innovation. Customers achieve environmental goals without sacrificing performance.”

Application Scenarios

Manufacturers can implement this technology across various applications:

- Automotive Electronics: Protect PCBAs in harsh vehicle environments

- Consumer Electronics: Safeguard smartphones and wearable devices

- Industrial Controls: Protect PLC and DCS systems from contamination

- Medical Devices: Ensure reliability in critical healthcare equipment

Implementation Best Practices

Successful integration requires careful planning. Manufacturers should consider these steps:

- Assess current coating processes and pain points

- Evaluate production line compatibility and space requirements

- Plan PLC integration for automated control

- Train operators on new material handling procedures

- Establish quality verification protocols

For complete industrial automation solutions that support sustainable manufacturing initiatives, explore PLCDCSHUB’s comprehensive product portfolio featuring advanced control systems and process automation technologies.

Market Impact and Future Outlook

Sustainable electronics manufacturing gains momentum globally. PFAS-free technologies represent the industry’s future. Nordson and actnano lead this important transition.

Manufacturers adopting these solutions gain competitive advantage. They meet regulatory requirements proactively. They also appeal to environmentally conscious consumers.

Frequently Asked Questions

How do PFAS-free coatings compare in performance to traditional options?

Actnano’s Advanced nanoGUARD coatings match or exceed traditional coating performance. They provide superior protection while eliminating environmental concerns.

Can existing Nordson systems be upgraded to support actnano coatings?

Yes, most ASYMTEK systems can be retrofitted with appropriate components. Nordson provides upgrade paths for current customers.

What industries benefit most from this technology integration?

Automotive, consumer electronics, industrial automation, and medical device manufacturers gain significant advantages. Any industry requiring reliable PCB protection can benefit.