Description

Product Overview

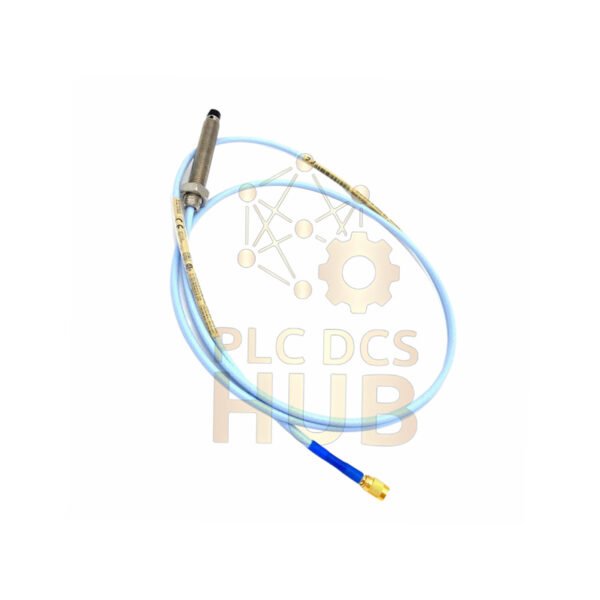

The Bently Nevada 3300 XL 8mm Probe is a premium eddy-current sensor. It delivers accurate vibration and position data for machine health monitoring. Its rugged design ensures long-term reliability in demanding industrial applications.

Complete Model Breakdown: 330101-10-43-10-02-05

- 330101 – 3300 XL 8 mm Proximity Probe

- -10 – Unthreaded Length: 1.0 inch

- -43 – Overall Case Length: 4.3 inches

- -10 – Total Cable Length: 1.0 meter (3.3 feet)

- -02 – Connector: Miniature Coaxial ClickLoc

- Standard cable attachment

- -05 – Certifications: CSA, ATEX, IECEx

- Approved for hazardous locations

Technical Specifications

- Brand: Bently Nevada

- Core Function: Vibration & Position Proximity Probe

- Measurement Range

- Linear Range: 2.0 mm (80 mils)

- Start Point: 0.25 mm from target

- Sensitivity (Scale Factor)

- Output: 7.87 V/mm (200 mV/mil)

- Tolerance: ±5% for standard 1/5m system

- Linearity (Deviation from Straight Line)

- Accuracy: Better than ±0.025 mm (±1 mil)

- Electrical Characteristics

- Probe Resistance: 7.59 Ω ± 0.50 Ω

- Cable Capacitance: 69.9 pF per meter

- Gap Setting: -9 Vdc (~1.27 mm / 50 mils)

- Frequency Response

- Depends on cable length to monitor

- Maximum Field Wiring: 305 meters

- Use shielded cable for best performance

- Operating Temperature

- Standard Probe: -52°C to +177°C

- Extended Range (ETR): Tip to +218°C

- Seal Warning: Avoid below -34°C before install

- Environmental & Mechanical

- Case: 303/304 Stainless Steel, 8mm diameter

- Tip: PPS Plastic with TipLoc molding

- Seal: Viton® O-ring for pressure differential

- Humidity: Stable (<3% change) in 93% RH

- Cable Strength: 75 lbf pull-off with CableLoc

- Optional Feature: FluidLoc cable available to prevent internal oil migration.

Installation & Compatibility

- Mounting: 3/8-24 UNF thread, 1.0″ unthreaded section.

- Wiring: Use 3-conductor shielded cable (16-24 AWG).

- System Compatibility: Works with Bently Nevada 3300 XL monitoring systems and compatible interfaces.

Packaging, Warranty & Shipping

- Package Includes: One fully assembled probe with connector.

- Warranty: 12-month guarantee against defects.

- Shipping: Fast delivery via FedEx, UPS, DHL.

- Support: Contact us at +86 158 8020 0923 for technical help.

Applications & Diagnostics

- Typical Uses:

- Continuous radial vibration monitoring

- Shaft axial position measurement

- Keyphasor reference for turbines and compressors

- Diagnostic Power:

- Enables early fault detection (imbalance, misalignment)

- Provides stable data for predictive maintenance programs

Frequently Asked Questions (FAQ)

Why choose an 8mm probe over smaller sizes?

The 8mm body provides superior physical strength. It better resists bending and damage in tough installations.

Is this probe safe for use in explosive areas?

Yes. The model suffix -05 confirms ATEX, IECEx, and CSA approvals for hazardous locations.

How do the length options work?

The suffix defines key dimensions. For example, -43 means a 4.3-inch case length for proper fit in your mounting hole.

What is the main risk during storage?

Storing below -34°C (-30°F) can damage the internal pressure seal. Keep probes in a controlled environment.

Can humidity affect the calibration?

Minimal effect. Tests show less than 3% sensitivity change after 8 weeks in 93% humidity.

When is the FluidLoc option necessary?

Choose FluidLoc if the probe installs where machine oil could leak through the cable’s core. It seals the cable interior.

Buyer’s Selection Guide

- Confirm System Type: Ensure compatibility with 3300 XL monitors.

- Check Required Lengths: Match the -10-43-10 suffix to your mechanical fit.

- Review Environment: For very high temperatures, specify the ETR version.

- Assess Fluid Risk: Select FluidLoc cable option if oil leakage is a concern.

- Verify Certifications: For hazardous areas, the model must end with -05.

Copyright © 2026 PLCDCS HUB Limited. All rights reserved.

Original Source: https://plcdcshub.com/

Partner: Powergear X Automation Limited | Oiltech Controls Limited

_副本-2-300x300.webp)

0.0 Average Rating Rated (0 Reviews)