The Role of 3300 XL Probes in Industrial Automation and Control Systems

The Foundation of Precision: Understanding 3300 XL Probes

Precision is non-negotiable in industrial automation. High-speed machinery requires robust monitoring. The Bently Nevada 3300 XL probe is a key component. This transducer measures displacement and vibration. It provides critical data for condition monitoring. Moreover, its unique design ensures stability. This is essential for reliable operation. Manufacturers rely on this technology.

Critical Factors for High-Speed Applications

Successful monitoring depends on several factors. Correct probe gapping is the first step. Proper mounting ensures data integrity. Environmental conditions also affect performance. Temperature and humidity must be considered. These probes are designed for harsh environments. They resist oil, water, and debris. Therefore, they are ideal for factory automation.

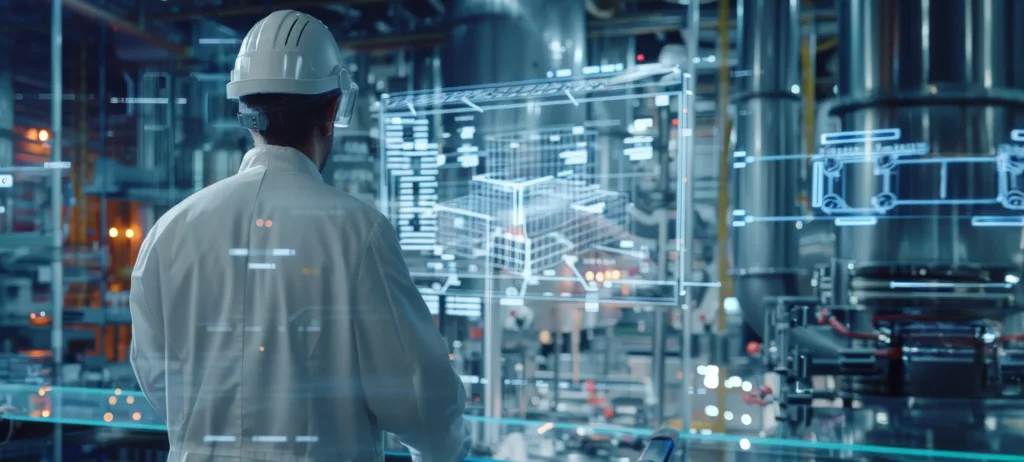

Integration with Control Systems for Optimal Performance

Data from the 3300 XL probe is just the beginning. The signal must be processed correctly. This is where control systems come into play. A PLC (Programmable Logic Controller) or DCS (Distributed Control System) is often used. These systems analyze the data in real time. They can trigger alarms or shut down machinery. This prevents catastrophic failures. Furthermore, seamless integration is vital. It ensures timely and accurate responses.

Ensuring Accuracy through Calibration and Maintenance

Accuracy is a continuous effort. Regular calibration is critical. Probes can drift over time. This can lead to inaccurate readings. Maintenance schedules should include probe checks. Cleaning the probe tip is also important. This prevents buildup that could affect measurements. A well-maintained system provides the best results. It protects valuable assets.

The Role of Expert Experience in Industrial Automation

My experience in the field confirms this. Simple errors can have major consequences. I have seen systems fail from minor misconfigurations. A simple mounting error can lead to noisy data. The real value is in expert implementation. We need to go beyond product manuals. Understanding the nuances of each application is key. This is the difference between good and great performance. It truly requires a holistic approach.

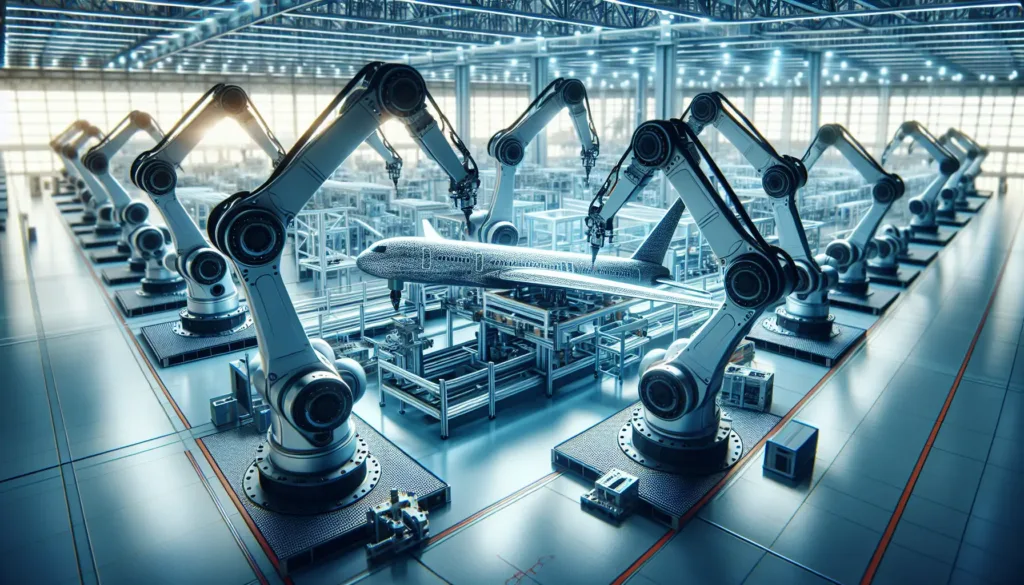

Practical Application Scenario: A Real-World Solution

Consider a gas turbine application. High-speed rotation generates significant vibration. The 3300 XL probes are mounted on bearing journals. They continuously monitor shaft position. This data feeds into a DCS. The system instantly detects any anomalies. It issues a warning and then takes action. This proactive approach prevents costly downtime. It safeguards both equipment and personnel.

Elevate Your Operations with Trusted Solutions

For top-tier industrial automation solutions, a trusted partner is essential. Our expertise at PLCDCS HUB Limited helps you maximize the performance of your machinery. We provide high-quality products and deep application knowledge.

Want to learn more? Explore our comprehensive product range for industrial automation now and discover how we can help you achieve unparalleled precision and reliability.

| Model | Title | Link |

|---|---|---|

| 330103-08-13-10-02-05 | Bently Nevada Proximity Probes | Learn More |

| 330103-05-15-10-02-00 | Bently Nevada Proximity Probes | Learn More |

| 330101-00-20-50-02-CN | Bently Nevada 3300 XL 8 mm Proximity Probe | Learn More |

| 330104-00-02-10-02-00 | Bently Nevada Proximity Probes | Learn More |