How to Extend Bearing Life by 40%: Advanced 3300 NSv Data Interpretation Techniques

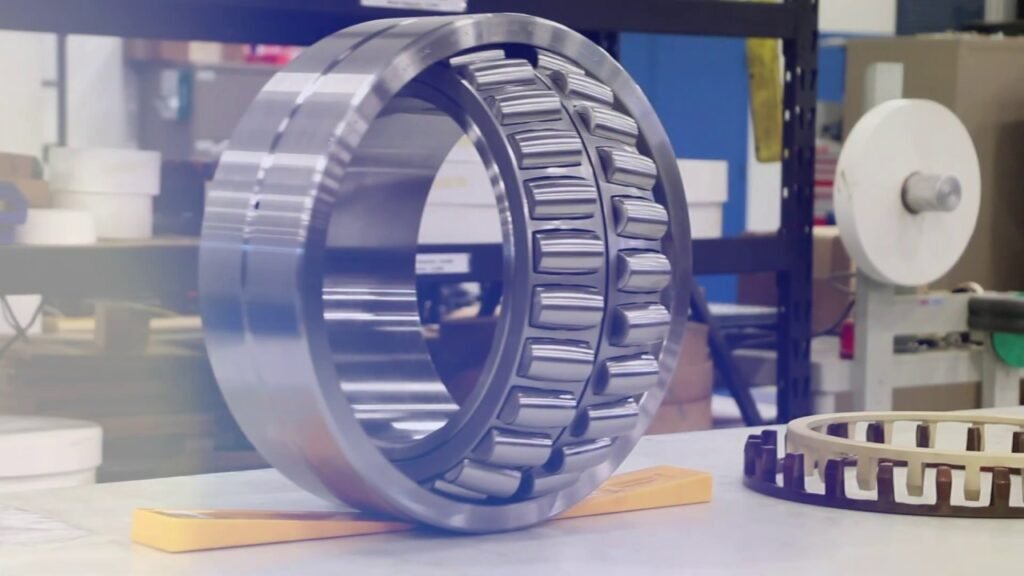

Understanding the Role of 3300 NSv Systems in Bearing Health

Modern industrial systems rely on precision monitoring tools like the 3300 NSv. This technology captures vibration, temperature, and load data to assess bearing health. Engineers use these insights to detect early signs of wear, enabling timely interventions.

Key Data Metrics for Predictive Analysis

Focus on vibration amplitude, frequency spectra, and thermal trends for actionable insights. High-frequency spikes often indicate lubrication issues, while uneven temperature patterns suggest alignment problems. Consistently tracking these metrics prevents unexpected failures.

Leveraging Real-Time Monitoring for Predictive Maintenance

Real-time data from 3300 NSv systems allows teams to shift from reactive to predictive strategies. Automated alerts flag anomalies before they escalate, reducing downtime. Integrating this data with maintenance schedules optimizes resource allocation.

Advanced Techniques for Data Interpretation

Apply machine learning algorithms to historical and real-time data. These models identify subtle patterns humans might miss, such as gradual load shifts or environmental impacts. Custom thresholds improve accuracy in fault detection.

Optimizing Lubrication and Load Management

Over-lubrication causes heat buildup, while under-lubrication accelerates wear. Use 3300 NSv data to fine-tune lubrication cycles. Similarly, balance operational loads to avoid excessive stress on bearings, ensuring longer service life.

Case Study: Achieving 40% Longer Bearing Life

A manufacturing plant implemented these techniques and reduced bearing replacements by 40%. By analyzing vibration trends, they adjusted lubrication schedules and corrected misalignments, saving $250,000 annually in maintenance costs.

Training Teams for Effective Data Utilization

Equip technicians with skills to interpret 3300 NSv outputs. Workshops on data visualization tools and root-cause analysis foster proactive decision-making. Cross-department collaboration ensures alignment between data insights and operational goals.

Future Trends in Bearing Health Management

IoT integration and AI-driven analytics will further refine predictive capabilities. Wireless 3300 NSv sensors and cloud-based platforms enable remote monitoring, pushing industrial automation toward smarter, self-correcting systems.

Check below popular items for more information in PLCDCS HUB Limited

| Model | Title | Link |

|---|---|---|

| 330901-00-90-10-11-00 | 3300 NSV Probe | Learn More |

| 330901-00-12-10-11-00 | 3300 NSV Probe (Without Armor) | Learn More |

| 330901-00-12-05-11-00 | 3300 NSV Probe | Learn More |

| 330901-00-52-10-02-05 | 3300 NSV Probe (Without Armor) | Learn More |

| 330901-00-08-10-02-RU | 3300 NSV Probe (RU Version) | Learn More |