PLC vs. DCS: How to Choose the Best Control System for Your Plant

Core Differences Between PLC and DCS

PLCs excel in discrete, high-speed tasks like assembly lines. DCS systems manage complex, continuous processes like oil refining. PLCs offer modularity for smaller setups. DCS integrates plant-wide control with centralized data handling.

Key Factors for Your Decision Matrix

Evaluate process complexity, scalability, and budget. PLCs suit flexible, low-cost projects. DCS fits large-scale, high-redundancy needs. Prioritize real-time performance and operator interface requirements.

Future-Proofing Your Automation Investment

Choose systems with open protocols like OPC UA. Ensure compatibility with IIoT and cloud platforms. Opt for vendors offering regular software updates. Plan for 10-15-year scalability.

Critical Applications for Each System

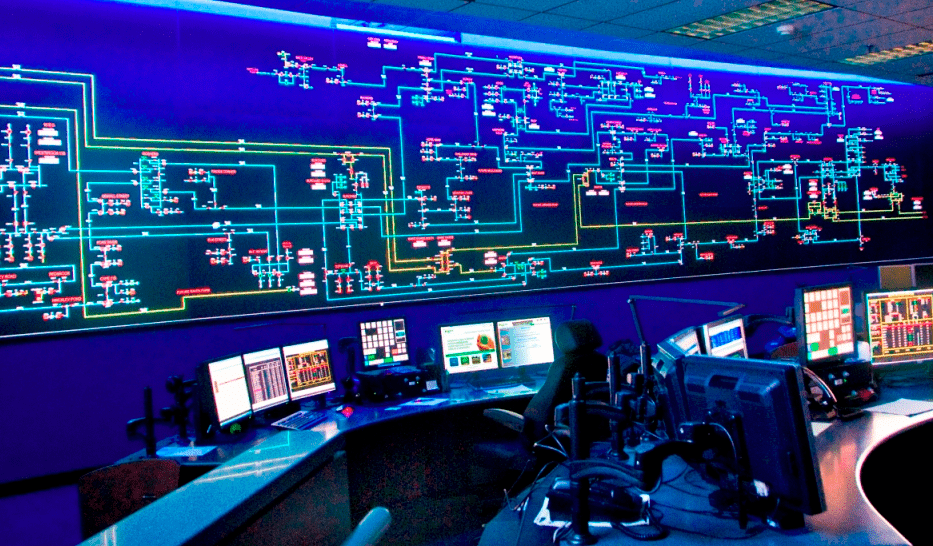

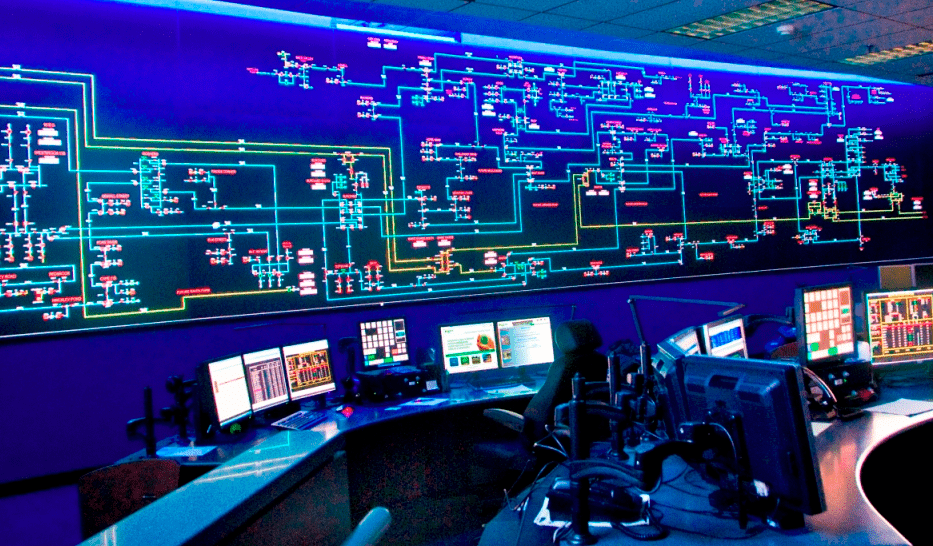

PLCs dominate packaging, automotive, and water treatment. DCS controls chemical plants, power grids, and pharmaceuticals. Hybrid setups combine both for mixed-process facilities.

Avoiding Common Selection Mistakes

Don’t assume DCS is always costlier long-term. Test cybersecurity features early. Involve operators in interface decisions. Benchmark against industry-specific standards like ISA-88.

Step-by-Step Implementation Strategy

Start with pilot testing on critical processes. Validate network bandwidth for data traffic. Train staff on system-specific troubleshooting. Schedule phased rollouts to minimize downtime.